Electric Forklift Battery [OP Battery]

Forklift Battery

The forklift, an essential material handling vehicle in factories and warehouses, operates on a dedicated battery.

The average lifespan of a forklift battery is approximately five years.

After five years,the battery needs to be replaced.

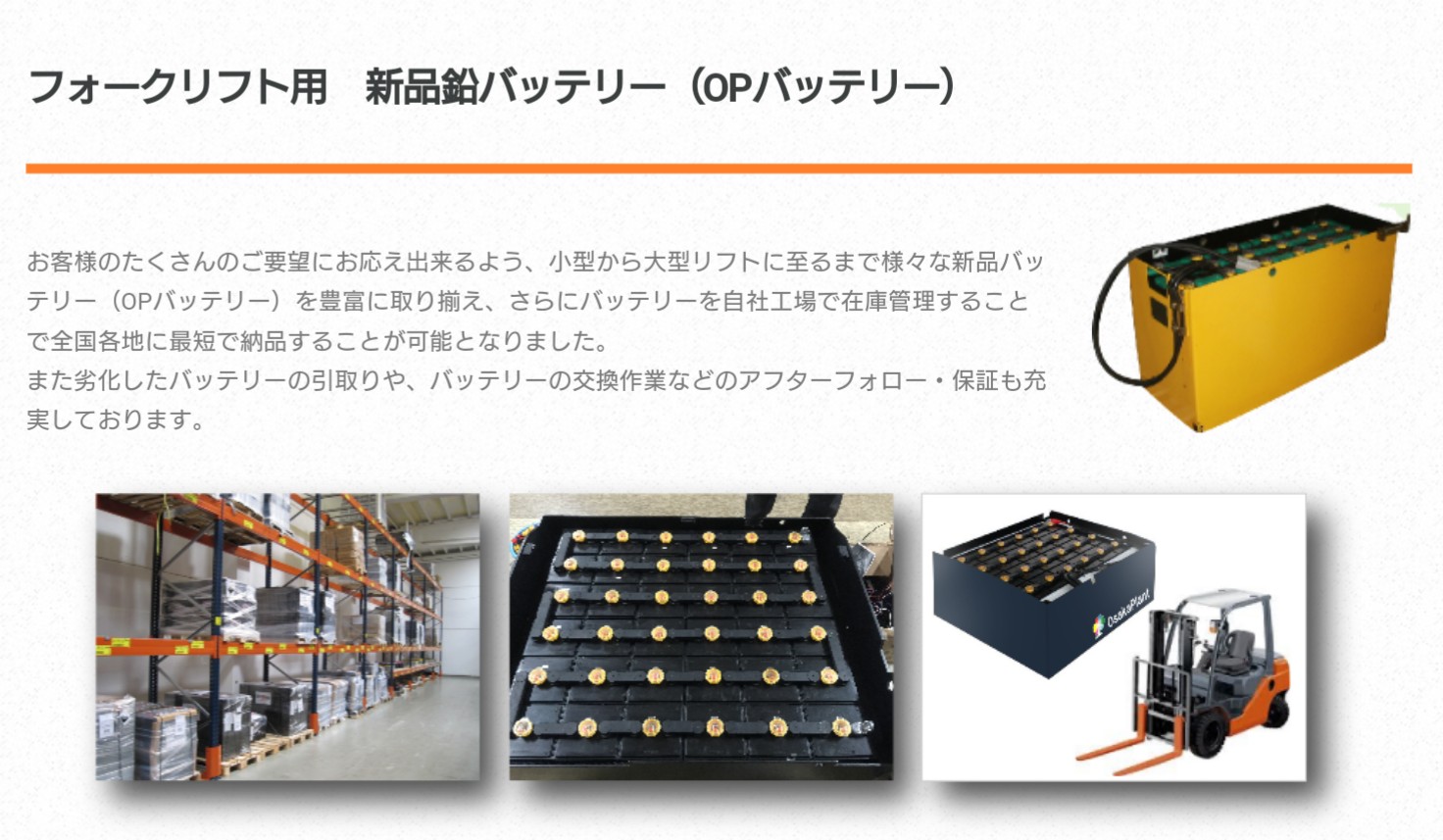

Many businesses are now turning their attention to the OP Battery as a cost-effective solution for forklifts, offering significant savings compared to purchasing a brand new battery.

In this article, we will delve into the performance and manufacturing methods of the OP Battery, making it a must-read for businesses considering OP Batteries for their forklifts.

OP Battery

<Cost Reduction with OP Battery! Achieve Enhanced Performance for Forklifts!>

The OP Battery refers to a lead battery designed for electric forklifts, manufactured by Osaka Plant Co., Ltd.

The OP Battery is tailored to meet the specific requirements of different types of forklifts.

It utilizes brand new cells, allowing it to deliver performance equivalent to that of a new battery.

Through the utilization of specialized expertise and equipment, a meticulous process is employed to eliminate defective cells and incorporate new cells into the battery.

The OP Battery is customized to match the type of forklift and its specific needs.

As a result, the OP Battery ensures the same level of reliability and outstanding performance as a brand new battery.

Maintaining Cell Balancing

Proper maintenance of cell balancing is crucial for improving battery performance.

The main cause of battery performance deterioration is “cell imbalance.” Various factors, such as the lifespan or malfunction of the forklift or the battery itself, can contribute to cell imbalance.

However, the OP Battery has gained attention for its ability to effectively maintain cell balancing.

By performing cell replacement with new cells using appropriate methods, it is possible to maintain proper cell balancing and enhance battery performance.

Differences between Reconditioned Batteries and OP Batteries

<Reconditioned Batteries>

Lead batteries for forklifts contain internal electrode plates.

When electricity flows, crystallization of a compound called lead sulfate occurs on these electrode plates.

This lead sulfate becomes a major factor in the deterioration of battery performance.

When a significant amount of lead sulfate accumulates, it obstructs the flow of electricity, resulting in sluggish forklift operation.

To address this issue, a method called “sulfation removal” is employed. It involves removing lead sulfate from used batteries.

By eliminating lead sulfate, the battery’s performance can be restored, and it can be reused as a reconditioned battery.

<OP Batteries>

OP Batteries, on the other hand, do not require sulfation removal as they involve the replacement of cells with new ones.

Hence, there is no need for the process. This allows OP Batteries to deliver performance equivalent to that of new batteries.

Furthermore, by using new cells, OP Batteries exhibit higher performance and reliability, offering superior characteristics compared to reconditioned batteries.

OP Battery Manufacturing Process

<Forklift Battery Collection>

We will collect used forklift batteries based on customer requests.

Our company handles the battery retrieval process promptly, carefully, and with a focus on safety.

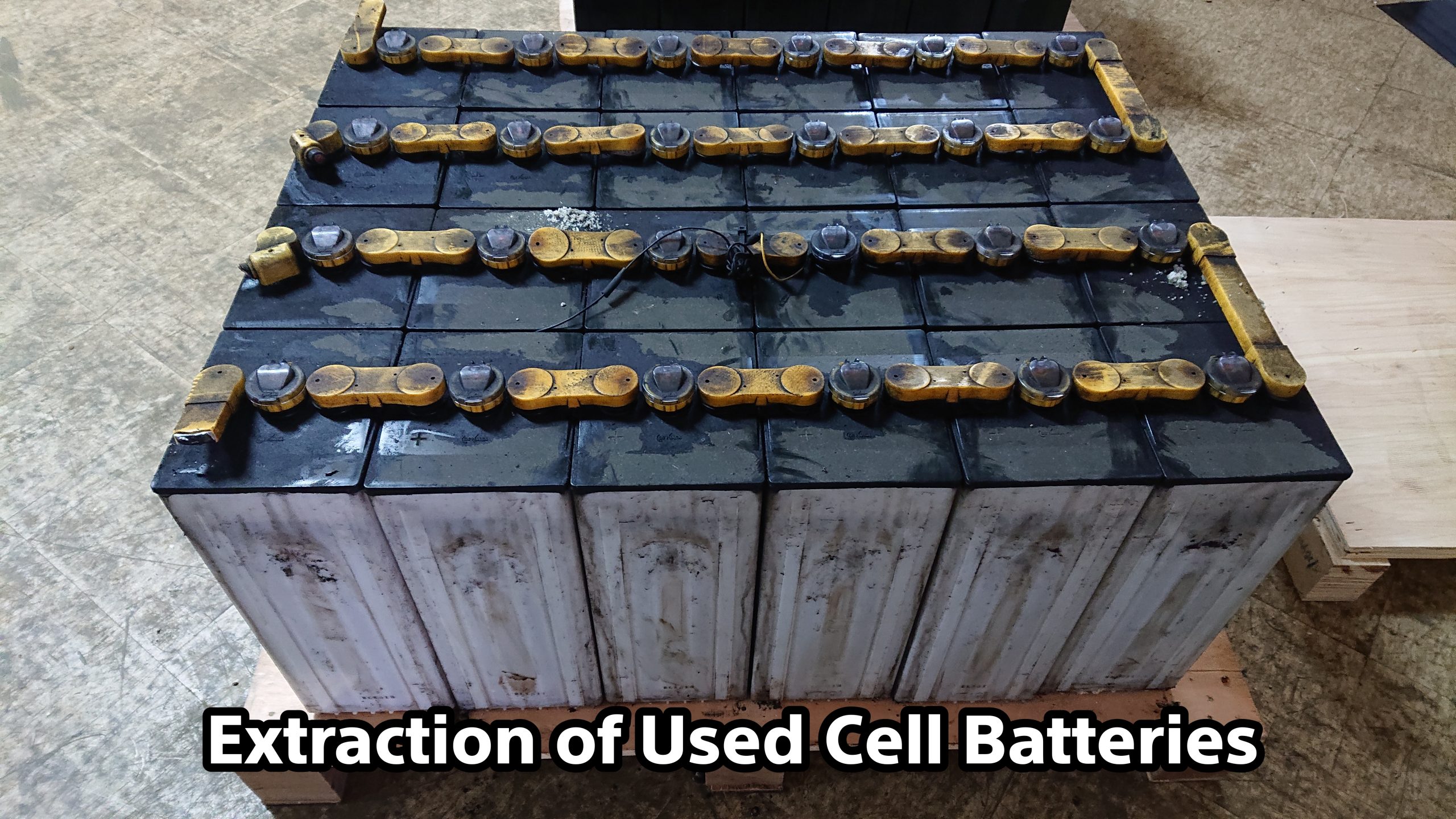

<Removal of Defective Cell Batteries>

Specialized workers carefully remove the used cell batteries.

Defective cell batteries are appropriately processed.

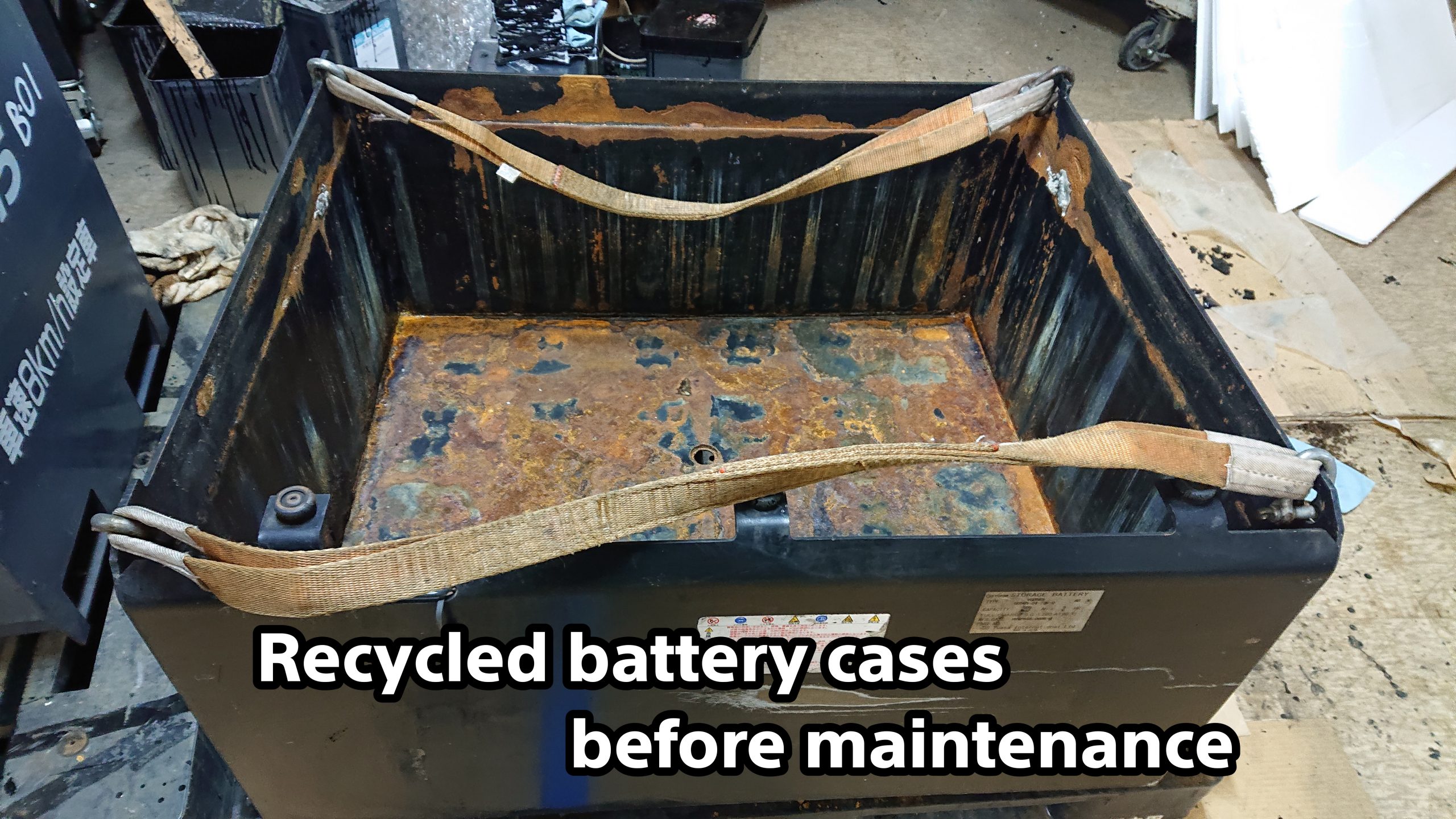

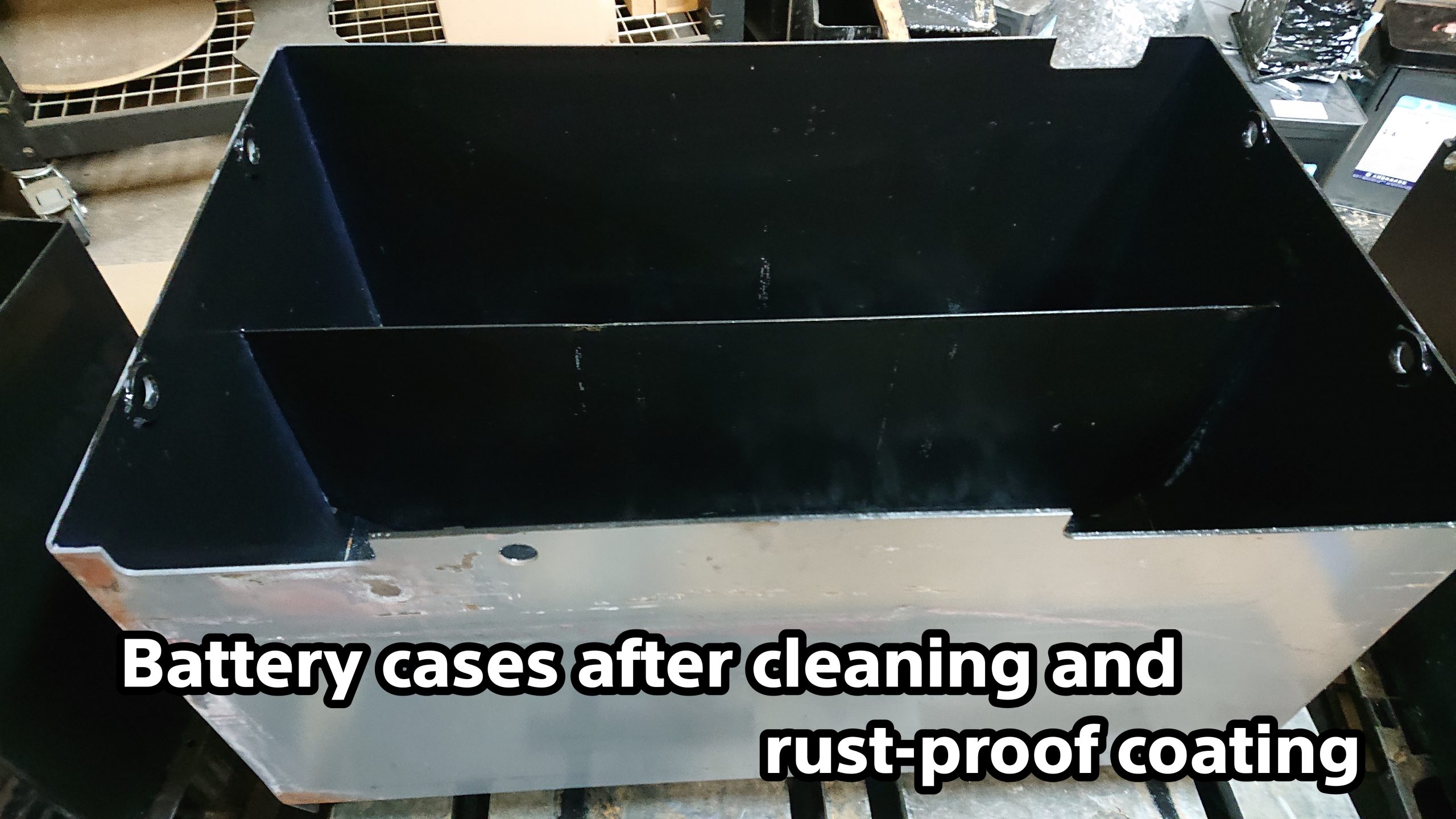

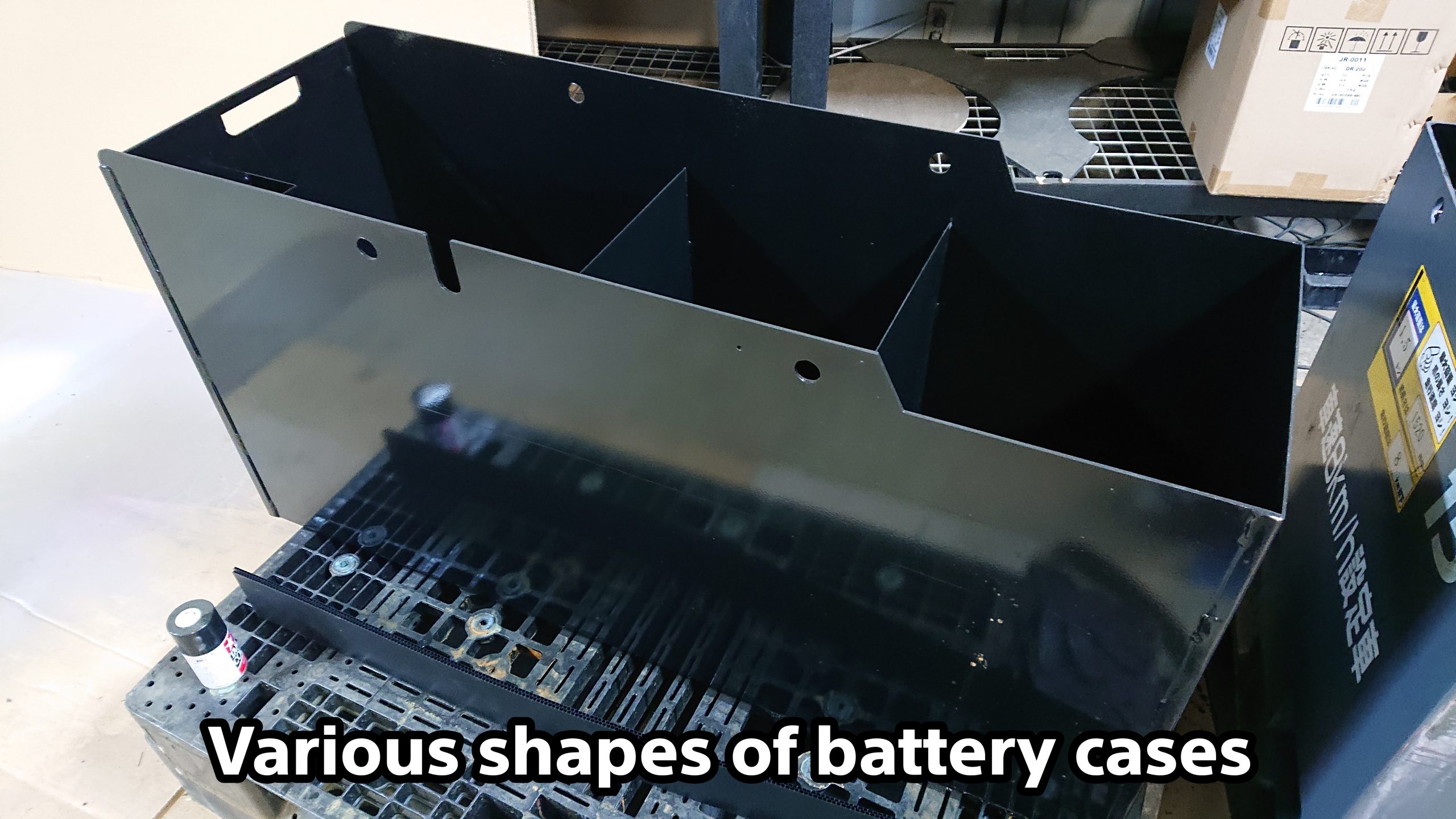

<Battery Case Maintenance>

To reuse the battery cases, we perform rust removal and cleaning.

Additionally, we apply paint to prevent rust and give the battery cases a polished appearance.

<Assembly of New Cell Batteries>

Using precise measurements, we accurately assemble new cell batteries into the battery cases.

Attention is paid to ensure a snug and gapless fit, and spacers are used as necessary.

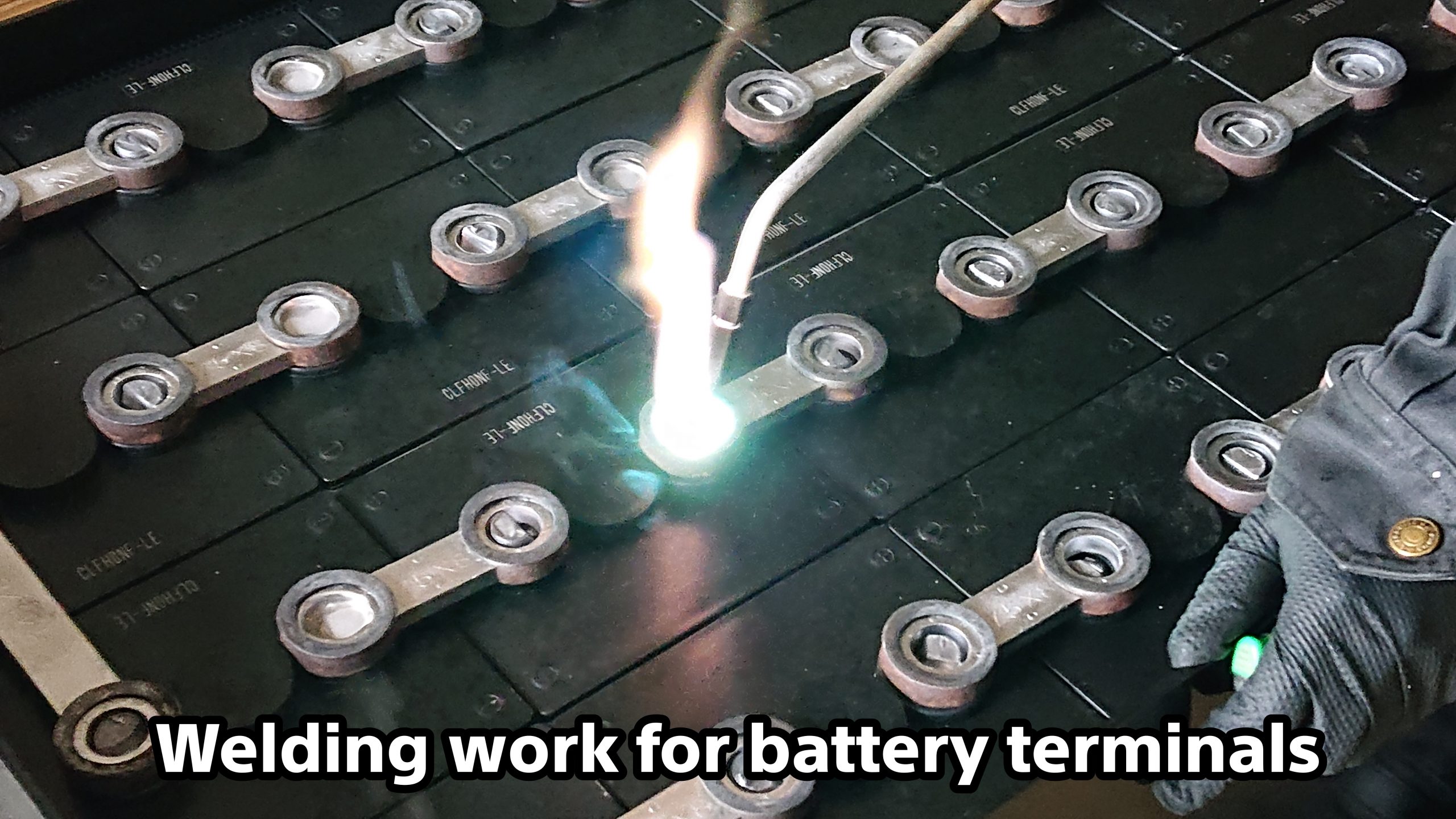

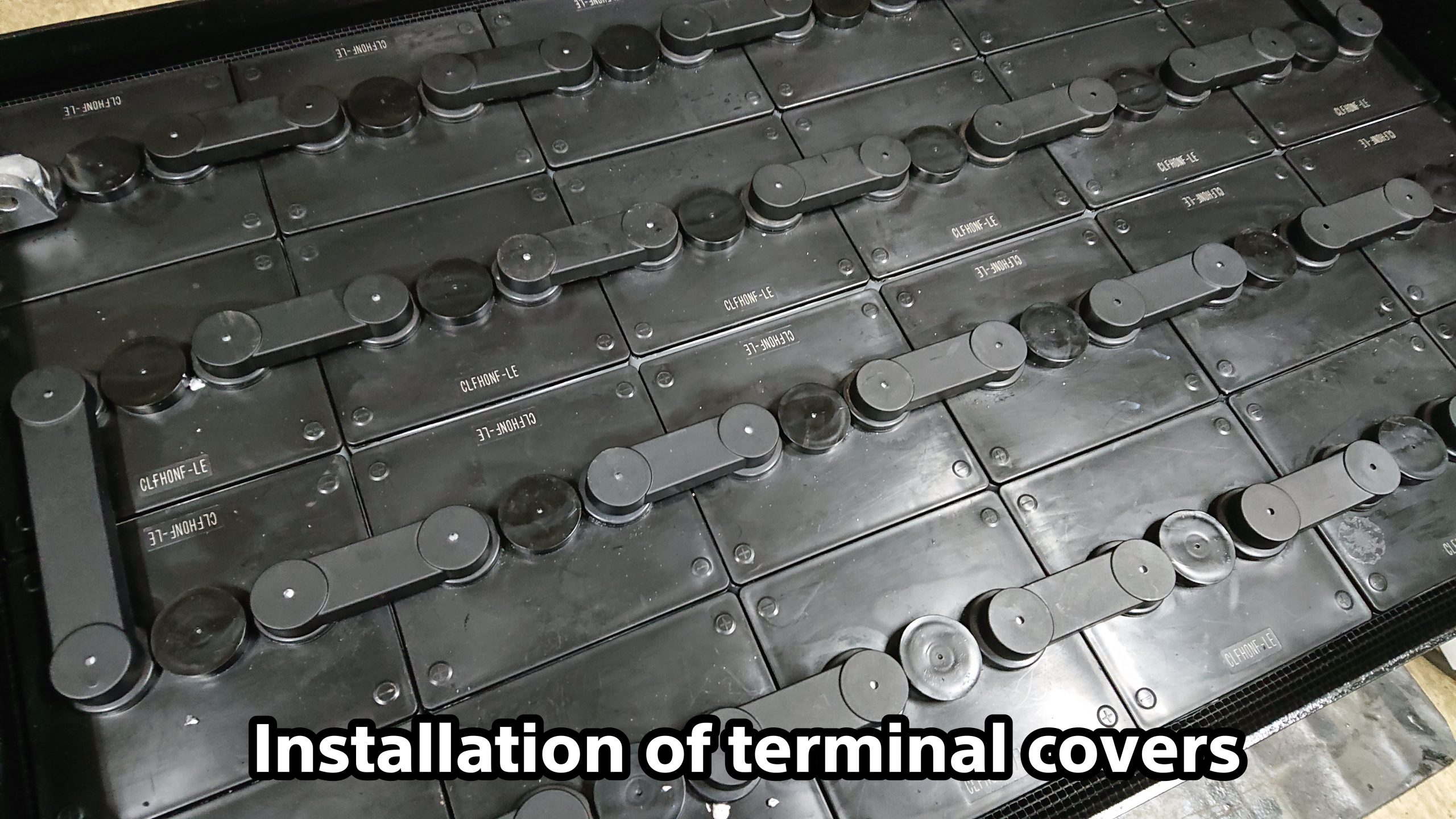

<Terminal Welding>

The terminal connections, using components called terminal lead, are welded onto the battery terminals.

This process ensures electrical connections within the battery.

<Wire Installation>

Wiring, including sensors and main harnesses, is installed.

This confirms the proper functioning of the battery’s features.

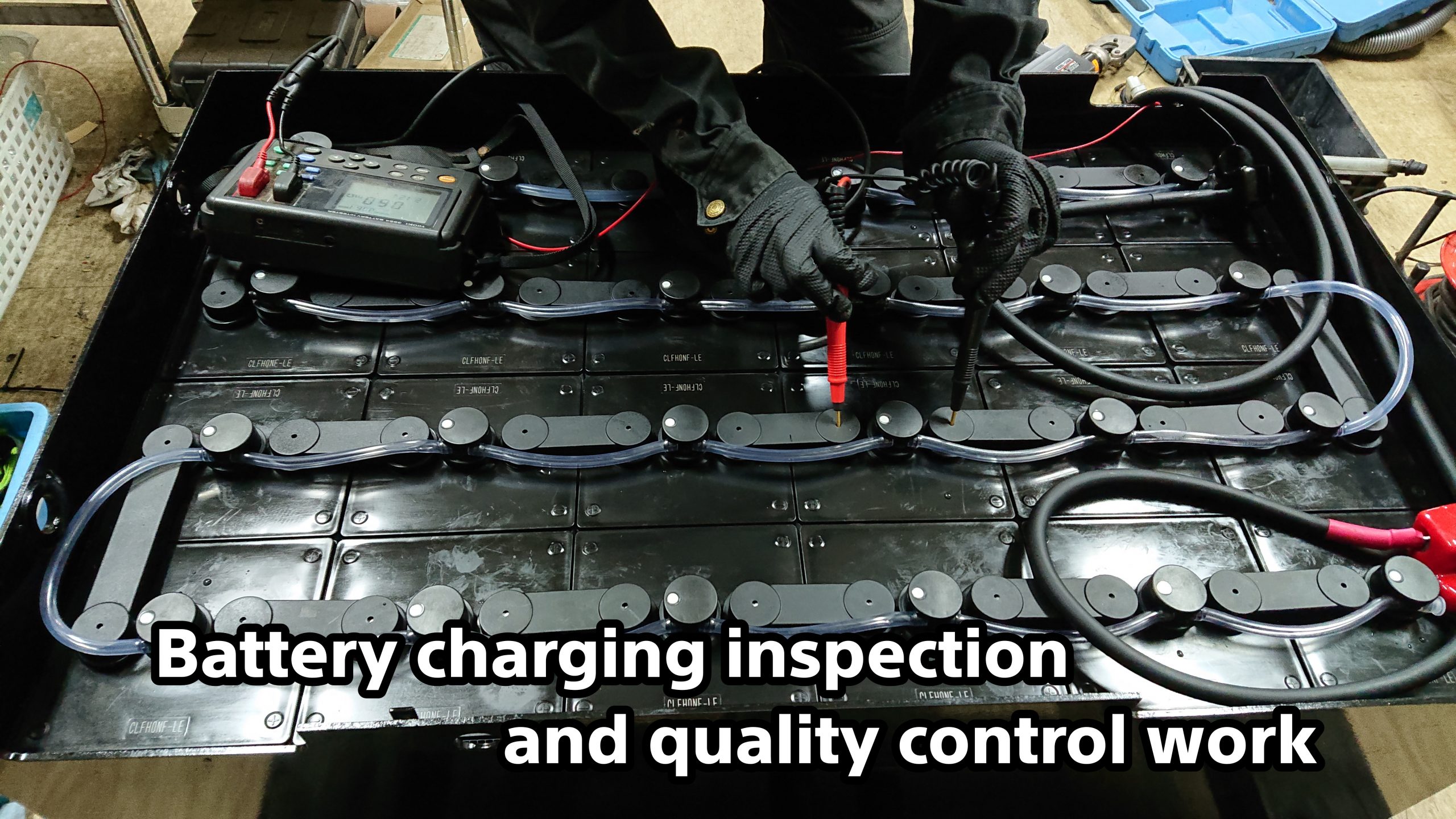

<Charging Inspection/Quality Control>

The battery is charged to the specified charging level, and an inspection is conducted to ensure proper charging.

Furthermore, quality control checks are performed to ensure the battery meets high standards.

<Completion of OP Battery>

Finally, after passing the inspection, the OP Battery is shipped to the customer.

The OP Battery, manufactured to meet the customer’s specifications, offers high performance and reliability.

Our company strives to provide batteries that meet the specific needs of our customers.

Electric Forklift Lead Battery [OP Battery]

Place your order here ↓ ↓ ↓

https://osakaplant.net/products-2/folkliftop/

〒542-0055

大阪府大阪市中央区船場中央1丁目2-1 船場センタービル1号館B1

TEL 06-4705-6680